Key Features of Bellows Seal Globe Valves

The bellows seal globe valve is designed to solve common issues faced by conventional valves, such as stem leakage and corrosion. Here are the standout features:1. Bellows Seal for Leak Prevention

The primary feature of a bellows seal globe valve is the bellows itself, a flexible, accordion-like metal seal that serves to protect the valve stem. This seal prevents the leakage of fluids around the stem, which is a common issue in traditional globe valves, particularly when handling aggressive media. The bellows design provides a reliable, leak-proof seal, ensuring that toxic or corrosive substances do not escape into the environment.2. Durability in Corrosive and Toxic Media

The bellows seal is particularly beneficial in environments where conventional valve seals may deteriorate quickly due to corrosive or abrasive fluids. It ensures that the valve stem remains shielded from the corrosive effects of media like acids, chemicals, or high-temperature fluids, increasing the valve’s lifespan and reducing the need for frequent maintenance or replacement.3. No External Leak Paths

Since the bellows is a flexible, welded component that creates a sealed enclosure, it completely eliminates the need for external packing or gland seals. This feature is particularly valuable in applications where even a small leak could pose safety risks, such as in the chemical, petrochemical, and pharmaceutical industries.4. Enhanced Operational Safety

The bellows seal not only prevents external leaks but also ensures the safety of personnel working around the valve. In critical applications involving hazardous fluids or gases, the bellows seal adds an additional layer of security by ensuring that harmful substances are contained within the system.Types of Bellows Seal Globe Valves

Bellows seal globe valves come in various configurations to meet the specific requirements of different applications. Some of the most common types include:1. Welded Ends Bellows Seal Globe Valve

This valve type features welded connections at the inlet and outlet, making it ideal for high-pressure and high-temperature applications where flanged or threaded connections might not provide the necessary strength. The welded ends ensure a tight, durable seal, making these valves suitable for extreme conditions in industries like oil and gas exploration.2. Flanged Bellows Seal Globe Valve

Flanged bellows seal globe valves have flanged connections at the ends, which make installation easier and more flexible. This type is commonly used in applications that require quick assembly or disassembly of the valve without compromising the integrity of the system.3. Socket-Welded Bellows Seal Globe Valve

Socket-welded bellows seal valves are designed for use in systems where the piping has a socket-welded joint. This valve type is highly effective in maintaining a secure, leak-proof seal in smaller pipelines, offering high strength and resistance to vibration and thermal expansion.4. Threaded Bellows Seal Globe Valve

Threaded bellows seal valves feature threaded connections, making them ideal for smaller pipelines where space is limited, or where valves need to be removed or replaced easily. These valves are also commonly used in systems requiring simple, compact designs.5. Extended Bellows Seal Globe Valve

The extended bellows seal globe valve has a longer stem and bonnet compared to standard models. This extended design provides additional protection for the stem and allows for easier access to the valve in certain systems. It's often used in systems where the valve is installed at a greater distance from the pipeline.6. Y-Pattern Bellows Seal Globe Valve

The Y-pattern design of this valve provides better flow characteristics by creating a streamlined path for the media. It is particularly useful in high-pressure systems or where minimal pressure drop is a priority. The Y-pattern design helps improve the valve's performance and reliability in a variety of industries.

How Does a Bellows Seal Globe Valve Work?

The Components

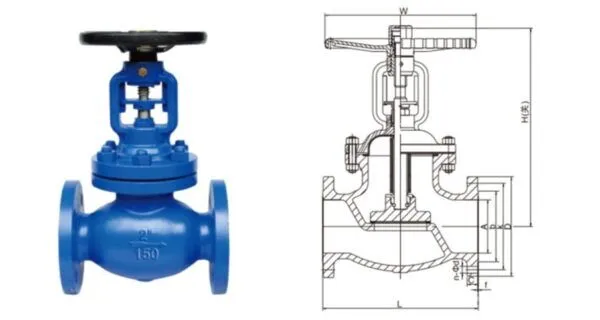

A typical bellows seal globe valve consists of several key components:Valve Body: The main structure of the valve that contains the flow path for the media.

Valve Disc: The movable component that controls the flow. It moves toward or away from the valve seat to open or close the valve.

Valve Stem: The part that connects the valve disc to the actuator. The stem is responsible for transferring the movement of the actuator to the valve disc.

Bonnet: The cover that houses the valve stem and seals the internal components. It is typically bolted to the valve body.

Bellows Seal: The key feature that separates the valve stem from the external environment and prevents leaks.

Packing: In some designs, packing may also be used in conjunction with the bellows to further prevent leakage, though the bellows generally provides a sufficient seal.

The Operational Principle

Open Position

Closed Position

Stem Protection

Applications of Bellows Seal Globe Valves

Chemical Industry

Oil & Gas

Petrochemical

Pharmaceuticals

Water Treatment

Conclusion

With various types of bellows seal globe valves available, including welded, flanged, socket-welded, threaded, and extended designs, there is a suitable option for every application. The valve's ability to prevent leaks, protect the stem from corrosion, and extend service life makes it an essential component in industries ranging from oil and gas to water treatment and chemical processing.

Whether you're looking for a valve to control the flow of harsh chemicals or to ensure the safe handling of high-pressure fluids, the bellows seal globe valve offers a versatile, durable, and cost-effective solution for reliable operation in critical applications.